AUTOMATIC IMPULSE

SEALER INSTRUCTIONS

For Model Numbers TISA-452, 602, 455, 605 & AIE MODELS AIE-300A1, 305A1, 450A1, 455A1, 600A1, 605A1 14", 18" AND 24" MODELS

OPERATING INSTRUCTIONS

1.Set power switch to ON position.

2.Set selector to MAN position for manual operation by pressing the foot pedal switch, or set selector to AUTO position for continuous automatic operation.

3.Adjust the re-cycle time, appropriate to the speed you need for continuous work.

4.Adjust the sealing time (heating time), to the THE LOWEST number on the timer that gives you a strong seal. Too low a number and the seal will easily pull apart. To high a number on the timer and the seal will just melt together instead of sealing. Use trail and error to achieve the lowest heat setting that provides a good seal. 5. Congeal time (also known as dwell time) is the amount of time the seal is allowed to cure under pressure AFTER THE IMPULSE HEAT IS OFF. Generally, this time should be set to 1 to 3 seconds longer than the sealing time.

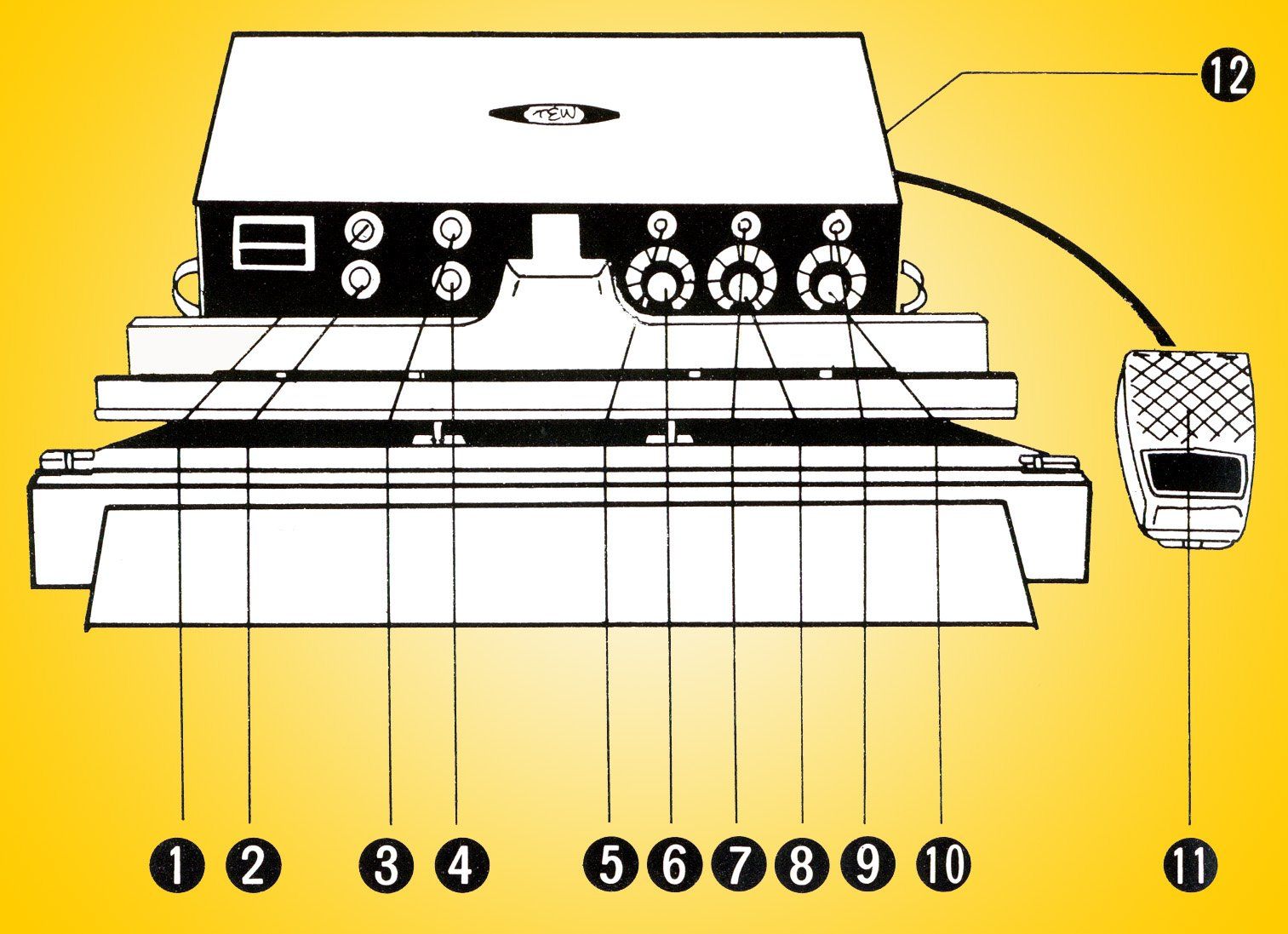

1. Power Indicator Light

2. Power Main Switch AUTO-Action Light

4. AUTO-MANUAL Action Selector

5. Re-Cycle Indicator Light

6. Re-Cycle Timer Control Knob

7. Congealing Dwell Time Indicatir Light

8. Congealing Dwell Timer Control Knob

9. Sealing Light

10. Sealing Timer Control Knob

11. Electric FootSwitch

12. Fuse

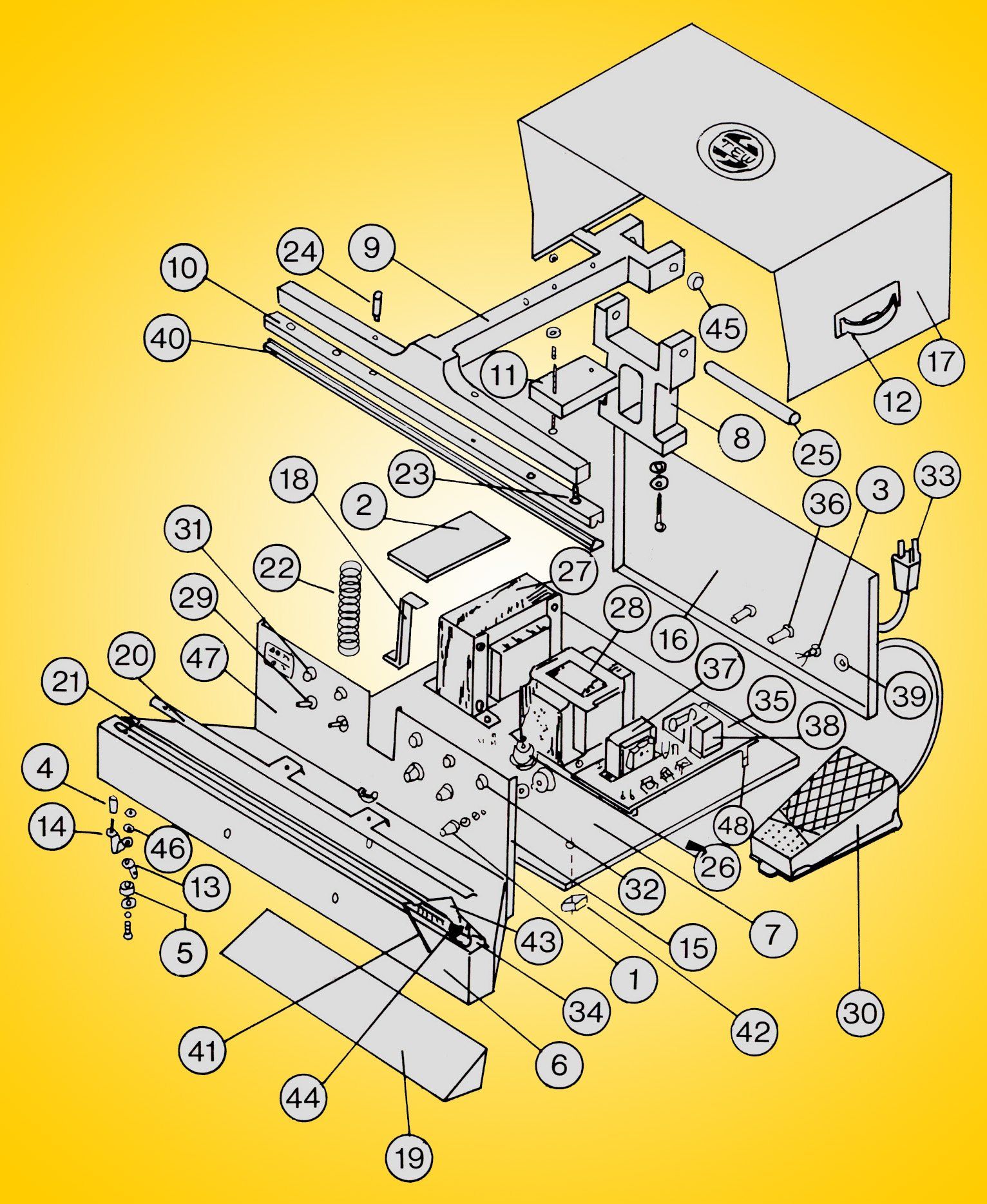

PARTS LIST

- Timer Knob

- Plastic Place

- Bushing

- Bakelite Pipe

- Convex Bakelite

- Lowe Jaw

- Base Plate

- Hinge Bracket

- Upper Jaw

- Upper Jaw Support

11. Flat Plate

12. Handle Strap

13. Brass Contact

14. Tension Spring

15. Front Plate

16. Back Plate

17. Top Cover Plate

18. Spring Lever

19. Operating Board

20. Clip for Cloth

21. Screw for Cloth

22. Return Spring

23. Spring for Upper Jaw

24. Screw for Upper Jaw

25. Hinge Pin

26. Spring Bracket

27. Trams Former

28. Solenoid

29. Toggle Switch

30. Foot Switch

41. Rubber String

42. Rubber Foot

43. Upper Barrier Tape

44. Bottom Barrier Tape

45. Pin Washer

46. Insulation Washer

47. Control Panel

48. PCB Support

31. Signal Light

32. LED Light

33. Power Supper Cord

34. Heating Element

35. Control PCS

36. Fuse Bracket

37. PCB-Trams Former

38. Relay

39. Connector Foot Pedal

40. Rubber Pressure Pad

MAINTENANCE AND CONSUMABLE PART REPLACEMENT

TURN OFF THE POWER BEFORE SERVICING THE SEALER.

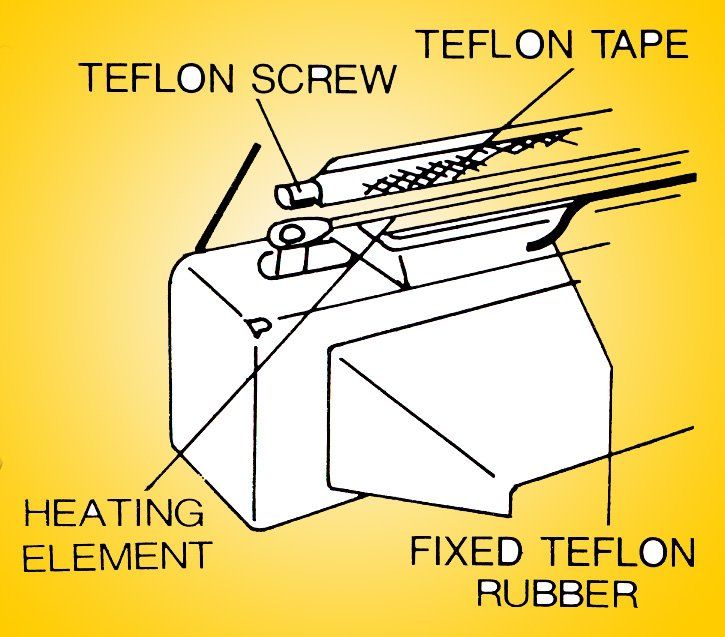

REPLACING THE ELEMENT WIRE

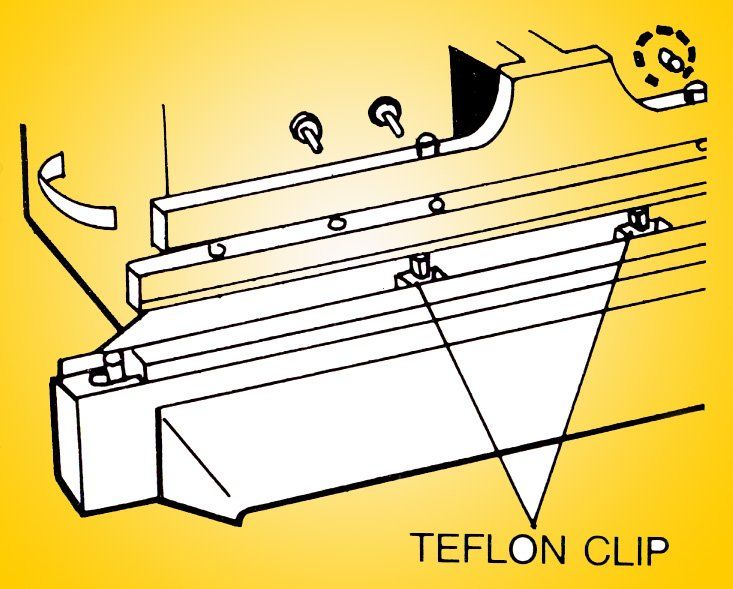

1. Release fixed rubber, or the chrome fabric clip so the Non-stick fabric can be moved, exposing the heating element.

2. Depending upon the model, remove the element wire by slightly moving the element wire spring pin inward toward the middle of the sealer or unscrewing the element wire so it can be lifted off the spring pin..

3. Replace the 1/2" by 10 mil PTFE (Non-Stick Heat Tape piece under the old element wire).

4. After attaching the new element wire, cover tightly with the Non-Stick PTFE fabric (pull out new fabric off the scroll if necessary) keeping pressure on the fabric as you re-tighten the clip or reinsert the black rubber depending upon the sealer model.

ADDITIONAL INFORMATION

Always keep the sealing platform clean.

Particular care should be taken to remove any melted plastic residue from the PTFE non-stick fabric scroll. Do not clean the sealing platform with anything wet.

If the bottom non-stick PTFE Heat Tape, (under the heating element) becomes worn, the heating element may short, and this will damage the element wire.

After a long period of extensive use the condition of the white silicone rubber top pressure pad should be examined for wear. Obviously any deformation will affect the quality of the seal. The white silicone pressure pad is easily replaced. We have them in stock.